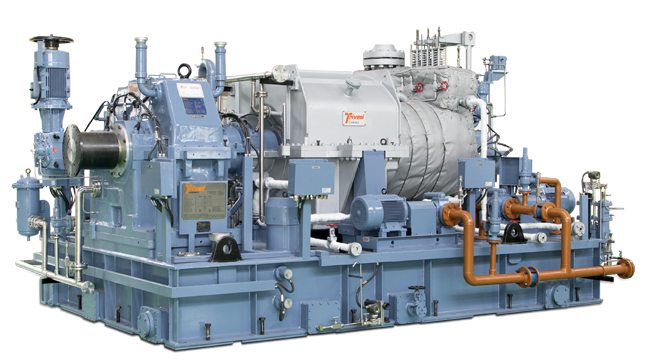

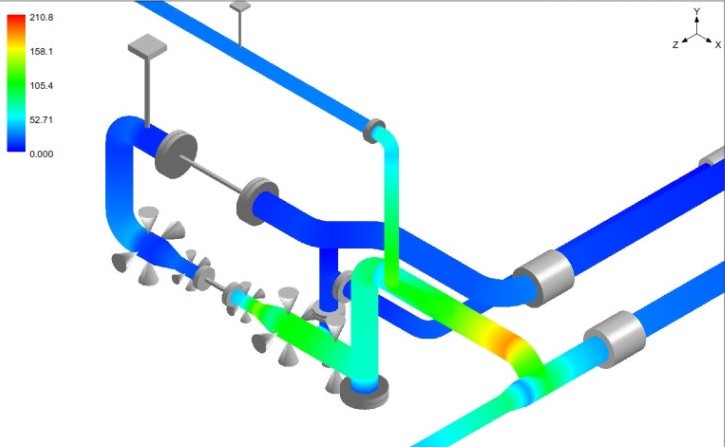

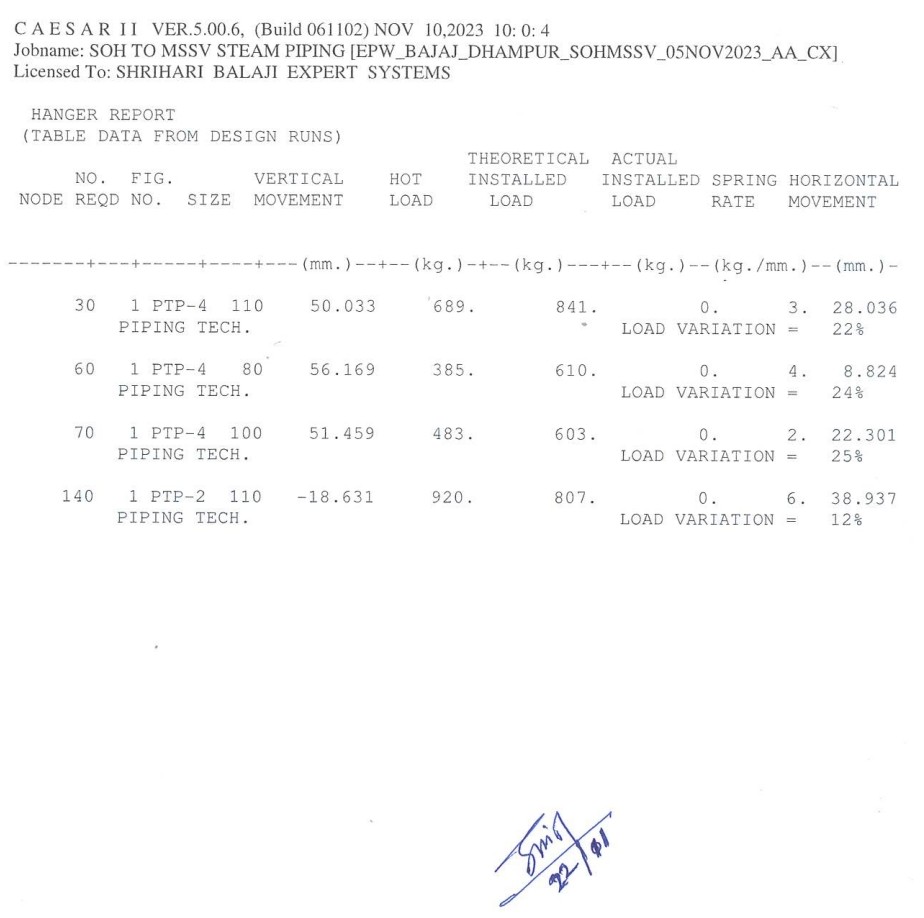

steam piping parallelity. steam distribution header to turbine inlet.(a)checking of stress analysis report with the actual installed steam piping.(b)recommendations comments as per the stress analysis report & actual installations at site.(c)marking of node numbers as per the stress analysis report.(d) checking & confirmation of supports, support types, spring hangers as per stress analysis reports.(e)ensure & validate supports & perform as the design requirements as per stress analysis.(f)load settings, support settings as per the stress analysis.(g) check the parallelity at 0 90 180 270 degree locations of the turbine inlet flange below 0.2mm or as per the turbine standard.(h)starting of the turbine for no load conditions, check confirm vibrations bellow the allowable limits of turbine standards.(I) performance of the turbine at different rated parameters of turbine design.(j)signing of the protocol with the turbine manufacturer of parallelity as per the turbine standard & design requirements.(k) successful performance of the turbine at hot load conditions.(l) successful mechanical & electrical overspeed trip.(j) successful operation as per the turbine standards.