Design solution for design of arrangement for trouble free performance of boiler without clinker formation.

references

performance data details as like videos site photographs our detailed discussions and Google meetings

details required with or after order finalization during execution

ultimate analysis of the fuels used

analysis of Ash

analysis of hard clicker formed in the furnace at different locations as like inner furnace walls, superheatur, boiler bank, economiser.

problem to be resolved in two steps.

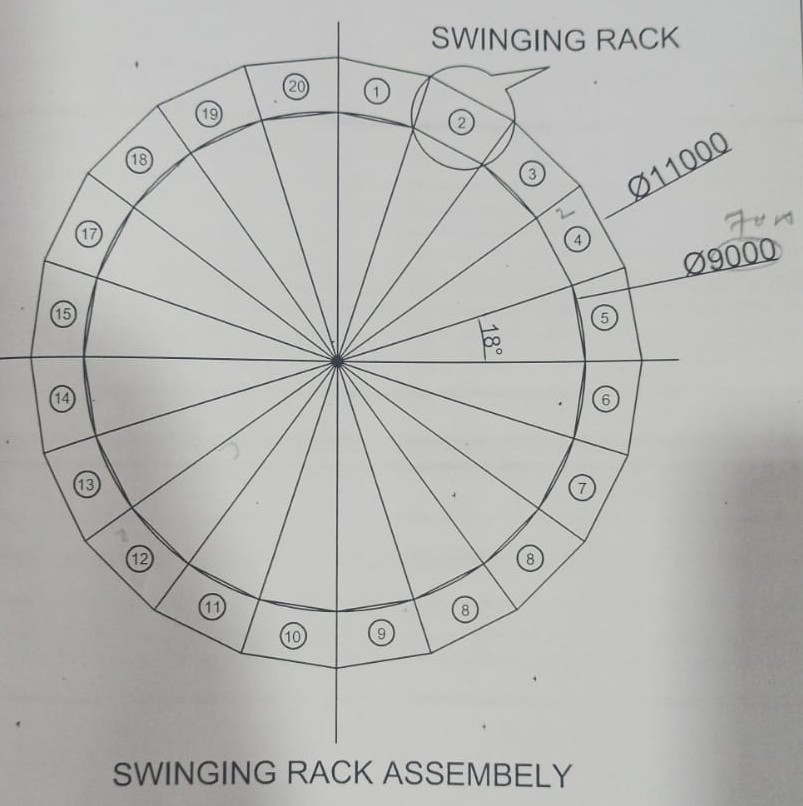

1. cleaning of furnace and removal of clinker preferably in running condition during operation or shut down.

2. Once the furnace superheater, boiler Bank, economiser areas are cleaned for the total clinker we propose an additional system for avoiding the overloading of furnace beyond the allowable loading conditions.

The options available are as like additional furnace for 25% of fuel burning which will input gas to the system to maintain temperature at the furnace exit below 725° C or in between 725 to 725 to 750 ° C.

a. addition of gas generators generating 25% of the gas of the total requirements

b. gasification system with Burner arrangement in furnace side walls.