Detailed Techno-Commercial Proposal for Efficiency Improvements in Water Tube Industrial Boilers

1. Executive Summary

This proposal aims to outline the technical and commercial aspects of implementing efficiency improvements in water tube industrial boilers. The objective is to enhance energy efficiency, reduce fuel consumption, and lower operating costs while ensuring compliance with environmental regulations.

2. Technical Proposal

2.1 Overview of Current System

Description of existing boiler setup.

Current efficiency metrics and performance indicators.

Identified inefficiencies and areas for improvement.

2.2 Proposed Efficiency Improvements

2.2.1 Boiler Design Enhancements

Heat Recovery Systems: Installation of economizers and air preheaters to recover waste heat from flue gases.

Superheaters: Incorporation of superheaters to increase the steam temperature, improving thermodynamic efficiency.

2.2.2 Combustion Optimization

Fuel-Air Ratio Control: Implementation of advanced control systems to maintain optimal fuel-air mixture.

Burner Upgrades: Replacement of old burners with high-efficiency models that ensure complete combustion.

2.2.3 Feedwater Treatment

Deaerators: Installation of deaerators to remove dissolved gases from feedwater, preventing corrosion and improving heat transfer.

Water Softening: Use of water softeners to reduce scale formation and improve boiler efficiency.

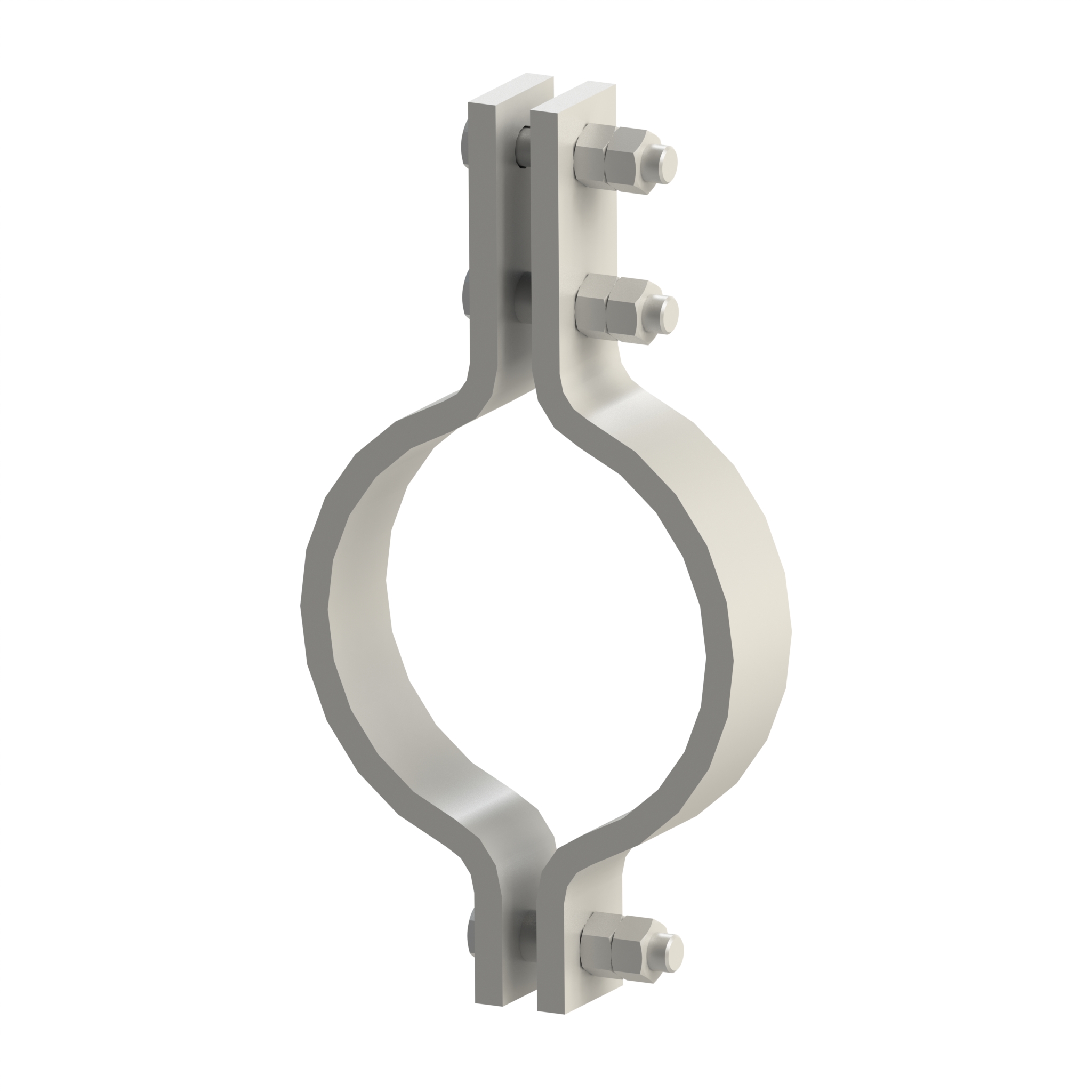

2.2.4 Insulation and Heat Loss Prevention

Insulation Upgrades: Improving insulation around the boiler and steam pipes to minimize heat loss.

Condensate Recovery: Implementation of a condensate recovery system to reuse hot condensate, reducing the need for fresh make-up water.

2.2.5 Control Systems and Automation

Advanced Control Systems: Integration of modern control systems for precise monitoring and regulation of boiler operations.

Automation: Use of automation for real-time performance monitoring and adjustments, reducing manual errors and downtime.

2.2.6 Alternative Fuels and Biomass Integration

Alternative Fuels: Exploration of alternative fuels such as natural gas or biomass to replace or supplement traditional fuels.

Co-Firing: Implementing co-firing techniques to use a mix of biomass and fossil fuels, reducing carbon emissions and fuel costs.

3. Commercial Proposal

3.1 Cost-Benefit Analysis

3.1.1 Initial Investment Costs

Detailed breakdown of costs for each proposed improvement.

Cost of equipment, installation, and integration.

3.1.2 Operational Savings

Projected reduction in fuel consumption.

Estimated savings in maintenance and operational costs.

Decreased water treatment and chemical costs due to improved water quality.

3.1.3 Return on Investment (ROI)

Calculation of ROI based on initial investment and projected savings.

Payback period analysis.

3.2 Financial Projections

3.2.1 Capital Expenditure (CapEx)

Total CapEx required for the implementation of improvements.

3.2.2 Operational Expenditure (OpEx)

Changes in OpEx post-implementation, including fuel, maintenance, and labor costs.

3.2.3 Revenue Projections

Potential increase in productivity and operational efficiency.

Impact on overall profitability and long-term financial health.

3.3 Funding Options

Available financing options and incentives.

Potential grants, subsidies, and tax benefits for energy efficiency projects.

4. Implementation Plan

4.1 Project Timeline

Detailed Gantt chart outlining the project phases, key milestones, and timelines.

4.2 Resource Allocation

Identification of required resources, including personnel, equipment, and materials.

4.3 Risk Management

Identification of potential risks and mitigation strategies.

Contingency plans for unforeseen challenges.

4.4 Quality Assurance and Compliance

Ensuring compliance with relevant standards and regulations.

Implementation of quality control measures throughout the project.

5. Conclusion

This proposal outlines a comprehensive plan to enhance the efficiency of water tube industrial boilers through technical upgrades and strategic investments. The anticipated improvements will lead to significant operational savings, reduced environmental impact, and enhanced profitability, providing a strong ROI for the initial investment.

6. Appendices

6.1 Technical Specifications

Detailed technical specifications of proposed equipment and systems.

6.2 Vendor Quotations

Quotations from potential vendors for equipment and services.

6.3 Case Studies

Case studies of similar projects showcasing successful implementation and benefits achieved.

6.4 References

References and credentials of key personnel and consultants involved in the project.

This detailed techno-commercial proposal provides a robust framework for implementing efficiency improvements in water tube industrial boilers, ensuring sustainable and cost-effective operations.